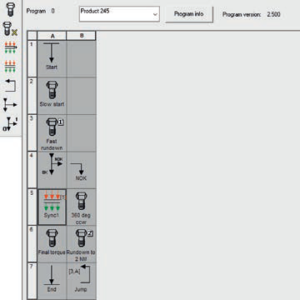

Bosch Rexroth offers numerous software options for its spindle tools, handheld tools, and wireless tools. Bosch Rexroth offers Windows Based BS350 software for the DC electric fixture spindles and DC electric handheld nutrunners. The BS350 software is icon based and has a maximum of 99 programs with 40 steps per program. Each step in the program can be monitored to ensure the joint is tightened to the required specification. The BS350 software package provides the ability to analyze torque graphs, view tightened results, and observe histograms as well as see the good range window on the final step in the rundown process.

Intuitive, Reliable Tightening Processes

System installation and programming of individual tightening tasks is done via convenient, icon-supported tools. Tightening processes are configures on

the graph interface.

Graph

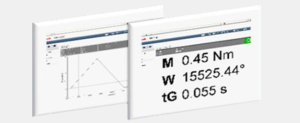

The tightening graph helps you quickly analyze tightening cases.

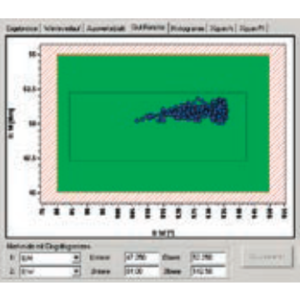

Good Range Window

The good range window clearly shows you the location of the tightening results in the target window.

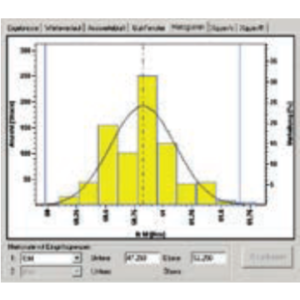

Histogram

The histogram gives you a quick overview of the statistical distribution of the tightening results.

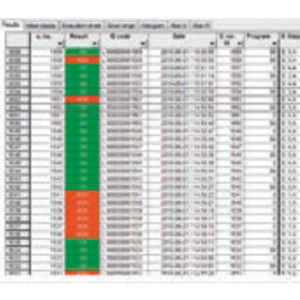

Results Window

Internal results memory of up to 40,000 tightening results and filter search functionallty.

Browser-Based Software

The browser-based software for the wireless Nexo tools is icon based and allows 256 programs to be created with 20 steps per program. Monitoring limits are possible for each step in the rundown. The wireless tool does not require software installed in any computer to program it. Instead, the software is browser-based and it is permanently embedded in the tool. The programming software can be accessed with any smart device that is connected to Wi-Fi using any browser, and accessibility can be limited if necessary. The tool can store up to 10,000 rundown results and each of the rundowns are viewable on the tool.

Responsive User Interface

Bosch Rexroth offers proprietary software programs that allow the user to extract data from the tool, view the data, analyze the data, and store the data on the tightening operations for future use. This software enables the users to view a live stream of the tightening system’s data from on-site or remote locations. The benefits of having this software include less downtime, consistency in production, and improved traceability.

Worker Guidance Displays

Worker guidance displays the correct bolt tightening sequence to the operator for a multi-bolt tightening operation. The program indicates the bolts to be tightened, bolts that have been tightened, and it provides real-time feedback on torque, time, and angle. Easy to create custom images allow for bolt sequencing patterns to be embedded into the image to show the operator the correct tightening pattern. This software enables visual control of the production environment.

Integrated PLC – IndraLogic

Bosch Rexroth offers and maintains a software development platform, IndraLogic, for PLC programming. The languages that the platform utilizes is Ladder logic, structured text, and more. With this software, programmers can control for all of the discrete inputs and outputs in station control and tightening systems. At the machine, this software allows control of lights, proximity switches, solenoids, valves, and more. The IndraLogic software is compliant with the industry standard IEC 61131-3.

Project Development

The overall system is uniformly and consistently projected for all solutions. User and multi-project management are available in all instances. The project and device explorers provide access to all system components. With its clearly organized dialog boxes, IndraWorks guides you intuitively through the configuration of your system.

Programming

The IndraLogic runtime system that is integrated in all solutions is consistently programmed in IndraWorks. The complete language scope specified in IEC 61131-3 is available. System-specific additional functions, such as motion blocks according to PLCopen or technology blocks, can be quickly and transparently implemented in your logic programs.

Tools

The tools for all engineering tasks are integrated in IndraWorks. Additional solution-specific tools are consistently available in the software framework.