Data Sheet 34: A Load Sensing Control Increases Pump and Circuit Efficiency

A number of pump manufacturers are now coming on the market with variable displacement piston pumps with a load sensing control. We believe this control will become increasingly popular because of its superior performance over a standard pressure compensator control.

A load sensing control has conventional pressure compensating action, but also has a flow compensator which responds to the volume of flow permitted to pass through the system flow control valve, and keeps pump displacement reduced to this exact amount at all times and under all conditions of loading. The total action of the control is to regulate the pump cam angle so the pump will produce only the flow needed at only the pressure required by the load. The result is the most efficient use of input power, the most precise control of the fluid power, and the least amount of oil heating of any system devised to date.

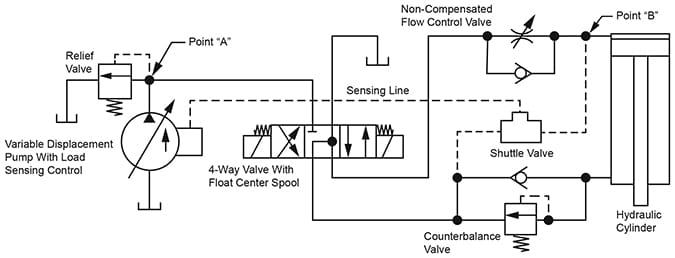

Figure 1. A typical circuit for a pump with a load sensing control.

Figure 1. Basic circuit showing the necessary elements of a system using the load sensing control. All components are catalog standard items, but knowledge and judgment are required to select them correctly.

Flow Resistance. The flow sensing part of the control compares pressure of the load at Point B with pressure in the pump line at Point A. It regulates pump displacement to maintain a constant 100 to 150 PSI pressure difference between these points. The measured pressure difference is due to oil flowing from the pump, through the plumbing, through the 4-way valve, and through the flow control valve. Pressure level at Point B is picked up through the shuttle valve and piped through the sensing line back to the pump control for comparison with pump line pressure.

Four-Way Valve. This valve must be of sufficient size to keep the pressure drop through it very low, say not more than 25 PSI. The higher it is, the less will be the “adjustment spread” on the flow control valve, and the more critical will be the speed adjustment.

This valve should have a blocked pressure port and vented cylinder ports in neutral. If either cylinder port should be blocked, the pump cannot unload against the closed pressure port in neutral. With both cylinder ports vented, the pump can idle at about 300 PSI at almost zero flow when the 4-way valve is centered.

Shuttle Valve. A shuttle valve must always be used regardless of whether speed is controlled in one direction or both. The purpose is to pick up a pressure signal from the cylinder port with the higher pressure, according to whether the cylinder is extending or retracting, and still to vent the “sensing line” in valve neutral. Without the shuttle valve and the open cylinder ports on the 4-way valve, the pump cannot unload when it becomes deadheaded in neutral.

Flow Control Valve. A non-compensated type must be used. The pressure drop through a compensated type is too high to be compatible with a load sensing control.

Meter-in type of speed control must be used. Load sensing controls will not work with meter-out speed control

Counterbalance Valve. Any auxiliary valving such as counterbalance, lock, or cushion valves must be placed between the cylinder port and the shuttle valve pick-up point, so they will not interfere with venting of the shuttle valve when the 4-way valve is placed in neutral.

Relief Valve. We recommend a relief valve with all pressure compensated pumps for added protection. The compensator, even if fast-acting, still requires a definite time to move the cam plate in the pump to zero displacement.

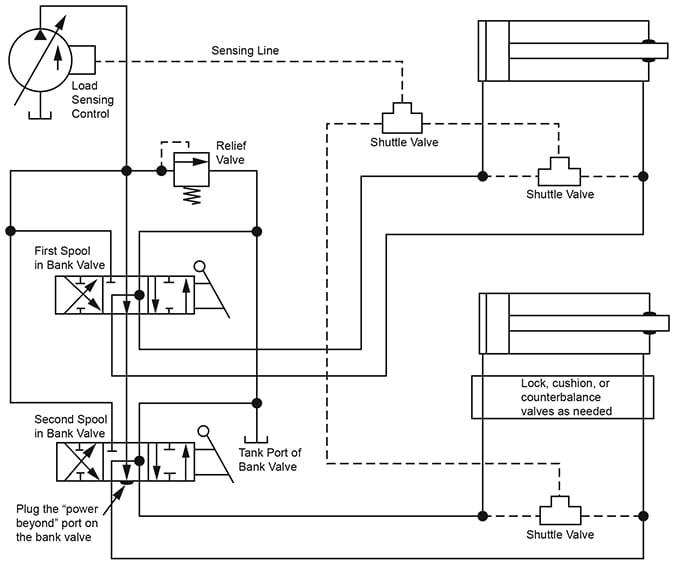

Figure 2. A typical bank valve application for a pump with load sensing control.

Figure 2. This is a typical application with a 2-section, manually operated bank valve. The load sensing control can used with most standard bank or stack valves, either parallel or series types, which meet the requirements described below. If the remainder of the circuit is correctly designed, at deadhead (in valve neutral) the pump will be working at zero flow and at a pressure of only 300 PSI, instead of at compensator setting. This improves efficiency.

Bank Valve. This valve must have a “high pressure carry-over” or “power beyond” port which is separate from its main tank return port. The power beyond port should be plugged so the pump will be deadheaded in neutral.

A mixture of spools in various sections of the bank valve not permissible with load sensing controls. All spools must have the porting shown, with both cylinder ports vented to the main tank port in neutral. Venting of the cylinder ports is essential to proper action of the load sensing control in deadheading the pump at a very low pressure.

Usually, separate flow controls are not used with bank valves. The handles are modulated to control speed in each branch. The pump will come on stroke far enough to supply the combined flow needed in all branches, and at a sufficient pressure to satisfy the branch with highest load.

Load holding checks must not be used in the cylinder ports of the bank valve. Lock, or counterbalance valves may be used if required, and placed in the location shown.

One important benefit of the load sensing control is the reduction of pump flow, at all load levels, to the exact flow required, and at a pressure only 100 to 150 PSI above the actual pressure needed on the load. This eliminates the necessity of discharging part of the oil across a relief valve, or of deadheading at the compensator pressure setting which,

of course, always shortens the life of the pump.

Another advantage is reduction of idling losses, particularly with bank valves having a large number of sections. In neutral, a high pump flow through many valve sections will produce a substantial power loss if the power beyond port is connected to tank. With the load sensing control, the pump can be deadheaded, and since it will build up only about 300 PSI at near zero flow, idling losses are negligible.

Instructions for lock, counterbalance, cushion, and shuttle valves are the same as described for Figure 1.

Additional information on load sensing controls and how they work, together with additional circuits, is available from your local Womack office. Give them a call.

© 1990 by Womack Machine Supply Co. This company assumes no liability for errors in data nor in safe and/or satisfactory operation of equipment designed from this information.