Data Sheet 76: NFPA Mounting Flanges and Shafts for Hydraulic Pumps and Motors

For many years the only standardization on pump and motor shafts and mounting flanges had been the SAE (Society of Automotive Engineers) Standard J744a. It was widely accepted by other industries as well as the automotive and is still a valid standard. The NFPA (National Fluid Power Association) started work in 1962 on a set of standards which would more directly apply to industrial fluid power pumps and motors, and would be more complete. This set of standards was unanimously approved by the NFPA Board of Directors and issued in 1965 as NFPA Recommended Standard T3.9.65.1. In 1966 it was also adopted by the ANSI (American National Standards Institute) and issued as B93.6-1966. It has since been revised and now carries the numbers ANSI B93.6-1972 and NFPA T3.9.2 R1. Copies are available from the NFPA.

The purpose of the standard is to encourage manufacturers to use interchangeable dimensions on both mounting flanges and shafts as far as possible to simplify dimensional interchangeability. No standards presently exist for foot mounting dimensions. No performance specifications exist although recommended methods of testing pumps and motors and the manner of presenting test data are given in NFPA Recommended Standard T3.9.17-1971.

The new NFPA and ANSI standards are similar to the SAE standards but differ in these respects: Additional shaft diameters and an alternative long length shaft have been added to the straight-shaft-without-thread listings. Additional mounting flange sizes have been added to provide a wider selection for the designer. NFPA has not assigned any horsepower ratings, making it the responsibility of the pump designer. However, the SAE horsepower ratings are shown for mounting flanges.

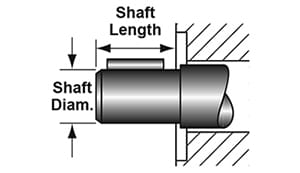

| STRAIGHT SHAFT (WITHOUT THREADS) | ||||||

| ANSI Shaft Code | Shaft Diam. Inches | Short Shaft Length Inches | Long Shaft Length Inches | Key Width Inches | SAE Shaft Code |  |

| 13-1 | 0.500 | 0.750 | – – – – | 0.125 | A-A | |

| 16-1 | 0.625 | 0.938 | 2.000 | 0.156 | A | |

| 22-1 | 0.875 | 1.312 | 2.500 | 0.250 | B | |

| 25-1 | 1.000 | 1.500 | 2.750 | 0.250 | B-B | |

| 31-1 | 1.250 | 1.875 | 3.000 | 0.312 | C | |

| 38-1 | 1.500 | 2.125 | 3.250 | 0.375 | C-C | |

| 44-1 | 1.750 | 2.625 | 3.625 | 0.437 | D, E | |

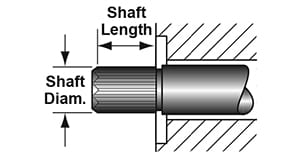

| 30° INVOLUTE SPLINE | |||||

| ANSI Shaft Code | Shaft Diam. Inches | Shaft Length Inches | Spline Specifications | SAE Shaft Code |  |

| 13-4 | 0.500 | 0.750 | 9T, 20/40 DP | A-A | |

| 16-4 | 0.625 | 0.938 | 9T, 16/32 DP | A | |

| 22-4 | 0.875 | 1.312 | 13T, 16/32 DP | B | |

| 25-4 | 1.000 | 1.500 | 15T, 16/32 DP | B-B | |

| 32-4 | 1.250 | 1.875 | 14T, 12/24 DP | C | |

| 38-4 | 1.500 | 2.125 | 17T, 12/24 DP | C-C | |

| 44-4 | 1.570 | 2.625 | 13T, 8/16 DP | D, E | |

| 50-4 | 2.000 | 3.125 | 15T, 8/16 DP | F | |

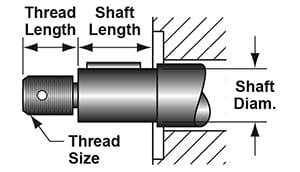

| STRAIGHT SHAFT (WITH THREADS) | ||||||

| ANSI Shaft Code | Shaft Diam. Inches | Straight Shaft Inches | Thread Size | Thread Length Inches | Key Width Inches |  |

| 13-2 | 0.500 | 0.750 | 3/8 – 24 | 0.532 | 0.125 | |

| 16-2 | 0.625 | 0.938 | 1/2 – 20 | 0.719 | 0.156 | |

| 22-2 | 0.875 | 1.312 | 5/8 – 18 | 0.906 | 0.250 | |

| 25-2 | 1.000 | 1.500 | 3/4 – 16 | 1.062 | 0.250 | |

| 32-2 | 1.250 | 1.875 | 1 – 12 | 1.219 | 0.312 | |

| 38-2 | 1.500 | 2.125 | 1-1/8 – 12 | 1.375 | 0.375 | |

| 44-2 | 1.750 | 2.625 | 1-1/4 – 12 | 1.562 | 0.437 | |

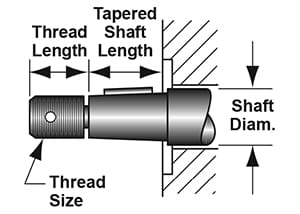

| TAPERED SHAFT WITH THREADS | ||||||

| ANSI Shaft Code | Shaft Diam. Inches | Tapered Shaft Length Inches | Threaded Shaft Length Inches | Thread Size | Key Width Inches |  |

| 13-3 | 0.500 | 0.688 | 0.500 | 5/16-32 | 0.125 | |

| 16-3 | 0.625 | 0.688 | 0.719 | 1/2-20 | 0.156 | |

| 22-3 | 0.875 | 1.125 | 0.906 | 5/8-18 | 0.250 | |

| 25-3 | 1.000 | 1.375 | 1.062 | 3/4-16 | 0.250 | |

| 32-3 | 1.250 | 1.375 | 1.219 | 1-12 | 0.312 | |

| 38-3 | 1.500 | 1.875 | 1.375 | 1-1/8-12 | 0.375 | |

| 44-3 | 1.750 | 2.125 | 1.562 | 1-1/4-12 | 0.437 | |

| 50-3 | 2.000 | 2.875 | 1.562 | 1-1/4-12 | 0.500 | |

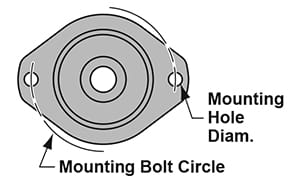

| MOUNTING FLANGE (TWO-BOLT) | ||||||

| ANSI Flange Code | SAE No. | SAE HP Rating | Mount. Bolt Circle Inches | Mount. Hole Diam. Inches | Pilot Diam. Inches |  |

| 50-2 | A-A | 5 | 3.250 | 0.406 | 2.00 | |

| 82-2 | A | 10 | 4.188 | 0.438 | 3.25 | |

| 101-2 | B | 25 | 5.750 | 0.562 | 4.00 | |

| 127-2 | C | 50 | 7.125 | 0.688 | 5.00 | |

| 152-2 | D | 100 | 9.000 | 0.812 | 6.00 | |

| 165-2 | E | 200 | 12.500 | 1.062 | 6.50 | |

| 177-2 | F | 300 | 13.781 | 1.062 | 7.00 | |

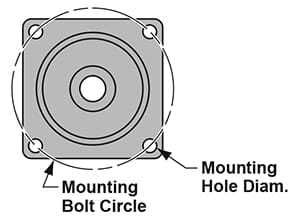

| MOUNTING FLANGE (FOUR-BOLT) | ||||||

| ANSI Flange Code | SAE No. | SAE HP Rating | Mount. Bolt Circle Inches | Mount. Hole Diam. Inches | Pilot Diam. Inches |  |

| 101-4 | B | 25 | 5.000 | 0.5625 | 4.00 | |

| 127-4 | C | 50 | 6.375 | 0.5625 | 5.00 | |

| 152-4 | D | 100 | 9.000 | 0.8125 | 6.00 | |

| 165-4 | E | 200 | 12.500 | 0.8125 | 6.50 | |

| 177-4 | F | 300 | 13.780 | 1.0625 | 7.00 | |

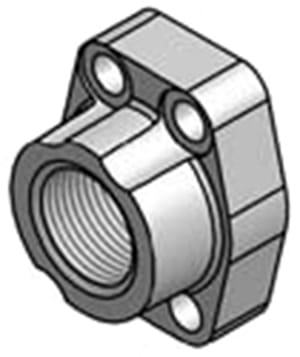

HYDRAULIC FLANGES FOR SAE PORTS

Standard (Low Pressure) Connection Flanges

Connects dryseal (NPTF) pipe threads, through an O-ring seal, to a mounting surface with rectangular bolt spacing.

| Nominal Size Inches | Rated PSI | Dim. A, Inches | Dim. B, Inches | Mounting Bolt Size | O-Ring Size |

| 3/4 | 5,000 | 1.875 | 0.875 | 3/8-16 × 1-1/2 | -214 |

| 1 | 5,000 | 2.062 | 1.031 | 3/8-16 × 1-3/4 | -219 |

| 1-1/4 | 4,000 | 2.312 | 1.188 | 7/16-14 × 1-3/4 | -222 |

| 1-1/2 | 3,000 | 2.750 | 1.406 | 1/2-13 × 2 | -225 |

| 2 | 3,000 | 3.062 | 1.688 | 1/2-13 × 2 | -228 |

| 2-1/2 | 2,500 | 3.500 | 2.000 | 1/2-13 × 2-1/2 | -232 |

| 3 | 2,000 | 4.188 | 2.438 | 5/8-11 × 2-3/4 | -237 |

High Pressure (6,000 PSI) Connection Flanges

Connects welded pipe through O-ring seal to a 4-bolt mounting surface or to another flange to make a union.

| Nominal Size Inches | Dim. A, Inches | Dim. B, Inches | Mounting Bolt Size | Pipe O.D. Inches |

| 3/4 | 2.000 | 0.937 | 3/8-16 × 1-1/2 | 1.063 |

| 1 | 2.250 | 1.093 | 7/16-14 × 1-3/4 | 1.328 |

| 1-1/4 | 2.625 | 1.250 | 1/2-13 × 2-1/4 | 1.672 |

| 1-1/2 | 3.125 | 1.437 | 5/8-11 × 2-3/4 | 1.923 |

| 2 | 3.812 | 1.750 | 3/4-10 × 3 | 2.406 |

| 2-1/2 | 4.875 | 2.312 | 7/8-9 × 3-1/2 | 2.906 |

| 3 | 6.000 | 2.812 | 1-1/8-7 × 4-1/2 | 3.547 |

Rectangular, 4-bolt connection flanges for pumps, motors, valves, and other components. Per SAE J518.

|  |

© 1990 by Womack Machine Supply Co. This company assumes no liability for errors in data nor in safe and/or satisfactory operation of equipment designed from this information.