Data Sheet 63: Troubleshooting Tips for Hydraulic Systems

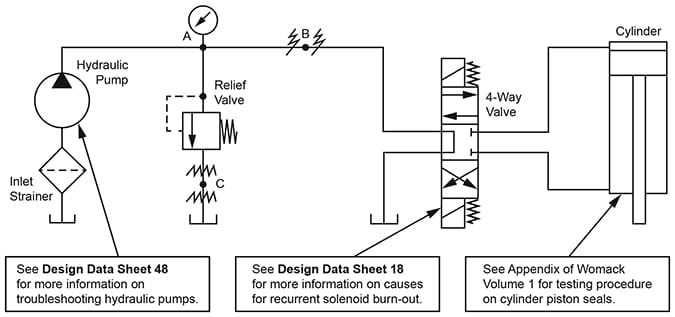

This data sheet describes a step-by-step check-out procedure for hydraulic systems which have previously been working satisfactorily but which have developed trouble, usually over a 24-hour working period, which renders them inoperative. It is not intended as a diagnostic check of new systems which may have been incorrectly designed. Other supplementary information on specific components such as pumps, cylinders, and valves will be found in other data sheet issues, and is referenced in the text. For checking out a system it is usually necessary to have at least one pressure gauge, installed in the pump line as shown in the diagram.

The diagram shows the major components used in nearly all hydraulic systems. Most system failures can be pinpointed to one of these components.

Basic Diagram for a Typical Hydraulic System

Symptoms

Many of the failures in a hydraulic system show similar symptoms: a gradual or sudden loss of high pressure, resulting in loss of power or loss of speed in the cylinders. The cylinder(s) may not move at all, or if they do they may move too slowly or may stall under light loads. Often the loss of power is accompanied by an increase in pump noise, especially as the pump tries to build up pressure against a load.

Of course, any major component pump, relief valve, cylinder, 4-way valve, filter, etc., could be at fault. And in a highly sophisticated system there are other minor components which could be at fault, but these possibilities are too numerous to be covered in this brief discussion of troubleshooting.

By following an organized step-by-step testing procedure in the order given here, the problem can usually be traced to a general area, then if necessary, each component in that area can be tested or can temporarily be replaced by another similar component known to be good.

Step 1 – Pump Inlet Strainer

Probably the field trouble encountered more often is cavitation of the hydraulic pump inlet caused by dirt build-up on the inlet strainer. This can happen on a new system after only a few hours operation as well as on a system which has been in service for a long time. It produces the symptoms described above: increased pump noise, loss of high pressure and/or speed.

If the strainer is not located next to the pump inlet, it will usually be found immersed below the oil level in the reservoir. Some operators are not aware of this strainer, or if they are, they do not give it attention until the system fails, at which time the pump may be ruined. If not regularly cleaned or replaced, sooner or later the strainer will become sufficiently restricted to cause a breakdown of the entire system.

The inlet strainer should be removed for inspection and should always be cleaned before re-installation. Wire mesh strainers can be cleaned with an air hose, blowing from the inside out. They can also be washed in a solvent, scrubbing them with a bristle brush. The solvent should be compatible with the hydraulic fluid in the tank. For example, kerosene may be used on strainers operating in petroleum oil. Avoid the use of gasoline, lacquer thinner, or other solvents which are explosive or highly flammable. The strainer should then be blown out whether or not it appears to be dirty. Some clogging materials cannot be seen except on very close inspection. If there are any holes in the mesh or if there is any apparent physical damage, the strainer should be replaced.

When re-installing the strainer, inspect all joints in the inlet plumbing for air leaks, particularly at union joints. There must be no air leaks in the pump inlet line. Check the tank oil level to be sure it covers the top of the strainer by at least 3˝ at minimum oil level, which is with all cylinders extended. If it does not, there is danger of a vortex forming above the strainer which may allow air to enter the system when the pump is running.

Notice the condition of the inlet hose (if one is used). A partially collapsed hose or one with internal swelling has the same effect as a clogged inlet strainer.

Step 2- Pump and Relief Valve

If cleaning the pump inlet strainer does not correct the trouble, isolate the pump and relief valve from the rest of the system by disconnecting the plumbing at Point B and capping both ends of the disconnected lines. This deadheads the pump into the relief valve. Start the pump and watch for build-up of pressure on the gauge while tightening the relief valve adjustment. If full pressure can be developed, obviously the pump and relief valve are operating correctly and the trouble is further down the line. If full pressure cannot be developed in this test, continue with Step 3.

Step 3 – Pump or Relief Valve

Further testing must be done to determine whether the pump or the relief valve is at fault. If possible, disconnect the tank return line from the relief valve at Point C. Attach a short length of hose to the relief valve outlet. Hold the open end of this hose over the tank filler opening where the rate of oil flow can be observed. Start the pump and run the relief valve adjustment up and down while observing the relief valve discharge flow. If the pump is bad, a full stream of oil may possibly be observed when the relief valve is backed off and this stream will greatly diminish or stop as the relief setting is increased.

If a flowmeter is available, the flow rate can be measured and compared with the catalog rating for the pump. If a flowmeter is not available, the flow can be measured by discharging the stream into a measuring container while timing with the sweep hand on a watch. Or, if the relief valve tank return line cannot be disconnected, the mechanic can place his hand in the discharge stream under the oil level in the tank to detect a drop-off in flow velocity.

During this test if the gauge pressure does not rise above a low value, say 100 PSI, and if the flow does not substantially decrease as the relief valve setting is increased, the relief valve is at fault and should be cleaned or replaced as instructed in Step 5.

If the flow decreases as the relief setting is raised, and only a moderate, but not full pressure can be developed, this indicates pump trouble. Proceed to Step 4.

Step 4 – Pump

If a full stream of oil isn’t obtained in Step 3, or if the stream diminishes markedly as the relief setting is raised, the pump may be worn out. Assuming that the inlet strainer has been cleaned and the inlet plumbing has been examined for air leaks or collapsed hose, the oil is slipping internally from outlet back to inlet. The pump may be worn out or the oil may be too thin. Excessively high temperature in the oil causes the oil to thin out and to slip excessively in the pump. High slippage in the pump will cause it to run much hotter than the oil in the tank. In normal operation with a good pump, the pump case may run 20 to 30°F more than the tank oil temperature. If greater than this, excessive pump slippage may be the cause.

Check also for slipping belts, sheared shaft key, broken shaft, broken coupling, loosened set screw, and other possible troubles listed in Design Data Sheet 48.

Step 5 – Relief Valve

If Step 3 has indicated the relief valve to be at fault, the quickest remedy is to replace it with one known to be good. The faulty valve may later be disassembled and cleaned. Pilot-operated relief valves have small internal orifices which may become blocked with dirt. Blow out all passages with an air hose and run a small wire through orifices. Check also for free movement of the spool. Pipe thread connections in the body may distort the body and cause the spool to bind. If possible, check for spool bind before removing threaded line connections, or while testing on the bench, screw pipe fittings tightly into the port threads.

Step 6 – Cylinder

If the pump will develop full pressure while operating across the relief valve in Step 2, both of these components can be assumed to be good. Test the cylinder piston seals as described in the Appendix to Womack “Industrial Fluid Power – Volume 1”.

Step 7 – Directional (4-Way) Valve

If the cylinder has been tested for piston leakage and found to have a reasonably tight piston, the 4-way directional valve may be checked for excessive spool leakage. It is rare that a valve becomes worn so badly that the pump cannot build up full pressure but it can happen. Symptoms of excessive leakage are a loss of cylinder speed -together with difficulty in building up to full pressure even with the relief valve adjusted to a high setting. This condition would be more likely to happen when using a pump with small displacement operating at very high pressure, and might have developed gradually over a long period of time.

See Design Data Sheet 18 for solenoid valve problems. Valves may be tested for leakage by the method given in the Appendix of “Industrial Fluid Power – Volume 1”.

Other Components

If the above procedure does not pinpoint the trouble, check other components individually. Usually the quickest and best troubleshooting procedure is to replace these components one at a time with similar components known to be good. Pilot-operated solenoid valves which will not shift out of center position may have insufficient pilot pressure. See information on solenoid valves in Womack “Industrial Fluid Power – Volume 2”.

© 1990 by Womack Machine Supply Co. This company assumes no liability for errors in data nor in safe and/or satisfactory operation of equipment designed from this information.